Quality, tradition and development are inseparabled terms with Honsberg company. Honsberg is today one from leaders at the marked of band saw blades. Companies arrond the world trust to the Honsperg products.

more at: www.honsberg.de

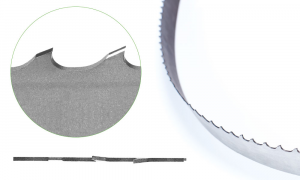

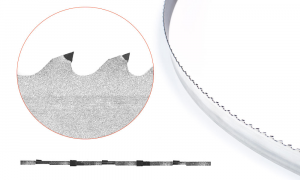

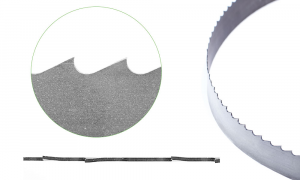

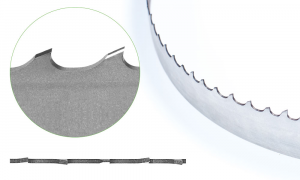

Bimetal bandsaw blade made of ~4% high chrome alloyed backing material and a HSS cutting edge made of HSS M42 / material No. 1.3247 with a cobalt content of 8%. The teeth hardness of approx. 68 HRc combined with a tenacious backing material with highbending fatigue strength is ideal for the cutting of all common steels grades up to a hardness of approx. 45 HRc in all diameters. Honsberg Spectra is the cutting solution for universal usage of bimetal bandsaw blades with mixed materials and diameters for all types of steel and machinery.

For universal usage for mixed materials (solids and structurals) and diameters for all types of steel and machinery.

S.....Tooth style S has a rake angle of 0°. Is is designed for cutting short chipping, low alloyed materials, solids in small and medium cross sections as well as tubes and profiles.

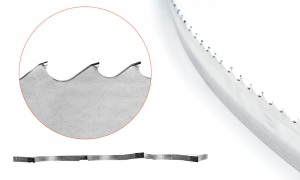

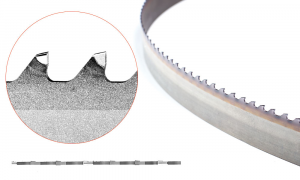

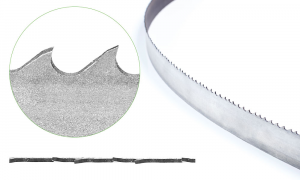

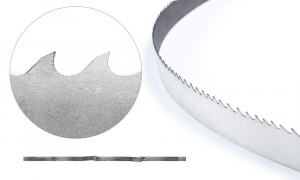

Bimetal bandsaw blade made of ~4% high chrome alloyed backing material and a HSS cutting edge made of HSS M42 / material No. 1.3247 with a cobalt content of 8%. The teeth hardness of approx. 68 HRc combined with a tenacious backing material with highbending fatigue strength is ideal for the cutting of all common steels grades up to a hardness of approx. 45 HRc in all diameters. Honsberg Spectra is the cutting solution for universal usage of bimetal bandsaw blades with mixed materials and diameters for all types of steel and machinery.

For universal usage for mixed materials (solids and structurals) and diameters for all types of steel and machinery.

K.....The hook tooth has a positive rake angle of 10°. It is especially suitable for cutting bigger cross sections.

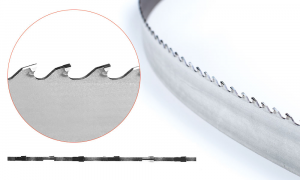

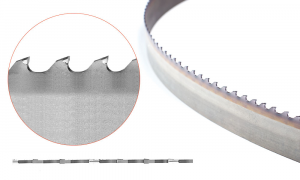

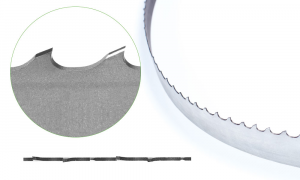

Bimetal bandsaw blade made of ~4% high chrome alloyed tenacious backing material and a HSS cutting edge made of HSS M42 / material No. 1.3247 with a cobalt content of 8% and a hardness of approx. 68 HRc. This blade with an aggressive cutting angle of 16° positive (see also Geometry-Tooth Forms) is designed to cut solids and thick walled tubes and structurals on 2-column and swing type machinery with low vibrations. The advantages of this blade are an easy cutting behavior with good chip formation and smooth cutting. All in all, this leads to an increase in life time compared to standard bimetal bandsaw blades.

Designed to cut and thick walled tubes and structurals on 2-column and swing type machinery with low vibrations. Also most recommendable to cut non-ferrous materials.

DELTA TOOTH D: Cutting angle extremly positive.

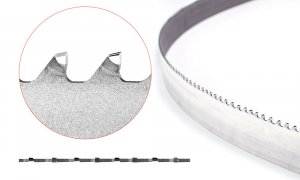

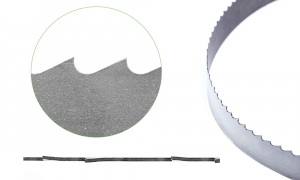

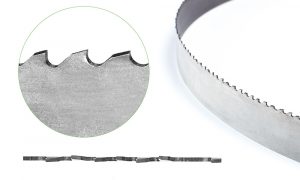

Bimetal bandsaw blade made of ~4% high chrome alloyed tenacious backing material and a HSS cutting edge made of HSS M42 / material No. 1.3247 with a cobalt content of 8% and a hardness of approx. 68 HRc. The cutting angle of 10° positive combined with a borazon ground Triple Tooth Concept with pre- and finishing cutters (see also Geometry-Tooth Forms) leads to an aggressive cut which is recommended for higher alloyed materials.

Suitable for cutting stainless steel, heat resistant alloys and titanium as solids on 2-column and block bandsaw machinery.

MASTER TOOTH M: Cutting angle is positive with defined tooth height difference. Suitable for: rustproof and acid-resistant steels, high cutting performance, long-chipping materials, solid materials.

Bimetal Bandsaw blade made of ~ 4% high chrome alloyed tenacious backing material and a HSS cutting edge made of HSS M42 / material No. 1.3247 with a cobalt content of 8% and a hardness of approx. 68 HRc. The special Secura tooth and set geometry prevents the blade from binding in the cutting channel, f.e. Heavy I... beams and structurals. The ultimate service life is reached by its shock resistant tooth style which absorbs vibration typical for structural cutting. Best for heavy structural or non ferrous metals.

Heavy structurals or non ferrous metals.

Bimetal bandsaw blade made of ~4% high chrome alloyed tenacious backing material and a HSS cutting edge made of HSS M42 / material No. 1.3247 with a cobalt content of 8% and a hardness of approx. 68 HRc. Honsberg Radial is the world-wide leading solution for cutting high- and highest alloyed solids on low vibration 2-column bandsaw and block bandsaw machinery for production cutting. Honsberg engineers managed to merge the 16° positive cutting angle (see also Geometry-Tooth Forms) with the reliable Triple Tooth Concept and a special set. The result is a highly aggressive cut behavior with excellent finish and highest cutting rates.

New development for cutting high and highest alloyed steels and alloys, nickel base superalloys on 2 column and block bandsaw machinery.

RADIAL TOOTH R: Cutting angle is extremely positive with a defined tooth height variation. Suitable for: rustproof and acid-resistant steels, high cutting performance, long-chipping materials, solid materials, longer service life (Honsberg Aurum).

Bimetal bandsaw blade made of 4 % chromium. The cutting part is made from high speed toolsteel HSS M51. Alloying with 10 % of cobalt and 10 % of wolfram mades the teeth edges hard as 69 HRC. Duratec M51 is suitable for cutting highly alloyed materials with hardness up to 50 HRC. High resistence against thermaů and abrasive factors enables the blade to achieve longer lifespawn especially when cutting large diameters of material.

Use: cutting of highly legates solids and thick wall tubes on machines that are vibration resistant. Designet to cut highter alloyed solids and tick walled tubec on low vibration machinery.

HOOK TOOTH K: Rake angle positive. Suitable for: universal use, profiles and solid materials, non-ferrous metals and steels.