| mm | 0° | 45° | 60° | -45° | -60° |  |

|

|---|---|---|---|---|---|---|---|

|

230 | 180 | 110 | x | x | x | x |

|

280x200 | 180x170 | 100x70 | x | x | 280x120 | 270x120 |

|

|

|

|

|

|---|---|---|---|---|

| 3x400V | 1,5 | 20-100 | 2720x27x0,9 | 780 |

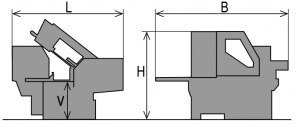

| Lmin | Lmax | Bmin | Bmax | Hmin | Hmax | V |

|---|---|---|---|---|---|---|

| 2305 | 2305 | 2260 | 2260 | 1405 | 1780 | 800 |

- It is a highly efficient automatic hydraulically controlled band-saw with multiple material feed.

- The machine is designed for vertical and angular cuts.

- Angles setting (turning of the bow) manualy:

- fluently between 0° and +45°right in automatic mode

- fluently between 0° and +60°right in semi-automatic mode

- The machine is designed to saw steel materials, but also non-ferrous and light metals.

- However, we recommend consulting the manufacturer about this option.

Control system:

- Machine is equipped with the control, programmable PLC MITSUBISHI FX5U.

- Blade drive as well as the feeder movements are fully controlled by the frequency inverters MITSUBISHI.

- The coloured touch screen MITSUBISHI GT 2104 enables easy communication with an operator. It shows working conditions (blade speed, cutting parameters etc.)

- The lenght and quantity are set by the control panel. Machine will optimize all next calculations itself. It is possible to set 15 different programms for quick lenghts setting.

- Type of material feed: Normal or INCREMENTAL

- Machine enables semi-automatic and automatic mode (all movements are controlled automatically).

- Regulation of shaft speed (moving to cut) is manual and uses throttle valve placed beside control panel. Automatic (safety) regulation of shift speed PEGAS BRP. Principle: Machine will stop after exceeding set loading (defined in ampers).

- The ergonomical control panel is mounted on the movable console. The control panel is equiped with mechanical buttons and digital display of the machine control system. Mechanical buttons controls basic saw movements (arm, vice, feeder) and cutting cycle start. The safety button is present on the panel aswell. Buttons for controlling the movements of the machine are part of a high-quality foil keyboard.

Construction:

- The machine is constructionaly designed in that way, so that it corresponds to standard exertions in productive conditions.

- The arm of the machine is made of cust iron and it is designed to ensure the power and the precision of the cut. Arm is 25 grades sloped, it increases the lifetime of

- The arm rotated by a shaft (joint) which is support by adjustableconical bearings

- Drive pulley and tighten pulley are both metal castings.

- Upper working arm position controled by automatic stopper (DPP)

- The down working position of the arm controlled by the miscroswitch. After reaching bottom working position the arm stops in the position set in the system.

- The vice is welded. Jaw ensures the safe clamping of the material.

- The hydraulically operating vice with long travel is placed in an adjustable dovetail groove.

- Moving jaw of the vice is handled by long stroke hydraulic cylinder.

- Very massive feeder moves using hydraulic cylinder and two sparpened bars and teflon cases.

- There is a floating seating of the feeding vice in the feeder, it means that the feeding vice moves in perpendicular sense regarding the feeding sense. The stationary jaw of the feeding vice copies the possible roughness of feeded material and the worning out of mechanical parts of the feeder is eliminated.

- The feeder moves the material to be cut to the main vice according to the set lenght that was adjusted by the operator in the controlling panel. The position of the feeder is indicated by electromagnetic sensor and measuring magnetic tape. For a perfect placing of a feeder , feeder moves to end positions by a slow velocity.

- Indication of material in the feeder: optic sensor - it notices that there is a material in the feeder. If there is no material in the feeder, the signal reflects on the glass that is situated on movable jaw and it goes back to the sensor. The machine stops feeding and waits for another bar.

- The vice is made from cast iron. Jaws ensure safe clamping of the material.

- Hydraulicaly controlled vise of the feeder. Moving jaw of the vice is placed in adjustabled dovetail groof and is handled by long stroke hydraulic cylinder in whole range.

- Turn table is cust iron.

- Manuall turning of the table for angle cuts, the position of the turntable is fixed by the lever with the excenter.

- Angles (degrees are shown at the touch screen MITSUBISHI. Angle indication using incremental sensor and a magnetic tape.

Basic equipment of the machine:

- The blade leading in guides with hardmetal plates and leading bearings and along cast iron pulleys.

- There is a guide situated on the firm beam on the drive side. On the tightening side there is the guide situated on the moving beam.

- The guide beams of moving band guide is adjustable. Manual adjustment and fixing of the guide beams.

- Guide holder moves in adjustabled dovetail groof.

- The saw-band is equipped with a guard, which protects the operator from millings and cutting emulsion.

- Mechanic tightening of the blade.

- Automatic indication of blade tension.

- Drive of machine is solved by worm gear box with maintenanceless oil filling. Three-phases electromotor with double winding, with a frequency converter for a fluent regulation of the blade speed from 20 to 100 m/min. Sturdy flange with shaft. Termoprotection of engine.

- The cooling system distributes cutting emulsion to the band guides.

- Massive base with a tank for chips. Base is designed for manipulation manipulation with machine by pallet truck and also by any hight lift truck.

- Indication of blade tightening and opening of the cover.

- Controlling 24 V.

- Machine is equipped with hydraulic system which controles all functions of that maschine. It pushes the arm to cut, pulls up the arm, opens and closes vices, moving of feeder.

Basic accessories of machine:

- Slide of cut pieces.

- Band saw blade.

- Set of spanners for common service.

- Manual instructions in eletronic form (CD).

Operating cycle:

The machine automatically grips the material in the main vice and the feeder moves into a position determined by the processor (i.e. the required length of the cut and a constant added length); the feeder-vice’s jaw stays open. The arm moves into the cut; after cutting the material, it moves into the upper position. The feeder moves by the constant added length (exactly to a position determined by the processor) and the feeder jaw grips the material. The vice is released; the feeder moves the material into the zero position (by the required length). The main vice grips, the feeder-vice is released and the entire cycle is repeated.The operator only removes the sawn material.

| Code | Description | Type | |

|---|---|---|---|

| MITSUBISHI HMI 4,3" | Control system MITSUBISHI with display 4,3“. | ST | |

| MITSUBISHI HMI 7" | Controlling panel with larger display – 7“ (standard = 4"). | OP | |

| ZAPSI | Industry 4.0, Connection to bandsaw monitoring and evaluation of machine efficiency, operation, production, and energy consumption. | OP | |

| F | Motor and frequency converter for a fluent change of the circumferential speed of the blade. | ST | |

| DPP | Mechanical workstop for upper frame position. | ST | |

| 240-CK | Cleaning brush of blade, driven passively (driven by sawing blade). | ST | |

| PEGAS-BRP | Electronical regulation of the down-shift. | ST | |

| 230-SKZ | Cut pieces slide. | ST | |

| PUD | Digital indicator of adjusted angle | ST | |

| 230-HP-A | Hydraulical upper vice for mounted on the main vice and on the feeding vice. | OP | |

| 230-RTS-A | Regulation press of vice – set of 2pcs for bothvices. | OP | |

| 230-VTT | Worm chip extractor for long chips (stainless-chips), included 1 pc of BOXTRI. | OP | |

| BOX-PCS | Box for cutted pieces with emulsion draining to the waterproof tank. | O | |

| BOX-TRI | Box for the chips with emulsion draining to the waterproof tank. | O | |

| BOX-TAH | Tool for manipulation with BOX-PCS and BOX-TRI. | O | |

| MINI LUBE 27-34 | Wasteless lubricating system, instead of emulsion cooling, specially for cutting profiles and non-ferrous metals, necessary supply of pressed air 6 Atm. | O | |

| LASER LINE | Laser indicator of cut position. | O | |

| LIGHT L1 | Lighting of working space. | OP | |

| 230-SET M42 | Set of 10 blades in M42 quality – with customer’s choice of teeth. 2720x27x0,9 | O | |

| 230-SET M51 | Set of 10 blades in M51 quality – with customer’s choice of teeth. 2720x27x0,9 | O | |

| WGUN1 | Spray gun for rinsing chips is used for a quick and easy cleaning of the machine from chips and burrs. | O | |

| 230 - NAV | Manual instruction – printed version. | O | |

| PAL2 | Packing on the palette 2,4 m x 2,4 m. | O | |

| OBAL2 | Package - wooden box 2,4 m x 2,4 m. | O | |

| OBAL-230-A | Packing in wooden cage. | O | |

| 230 RDZ | Output connecting part of the roller conveyor RD - ensures angle cuts of the machine, length 1000 mm, width 290 mm, bearing capacity 200 kg/m, adjustable leg includedd in price. | O | |

| RD 1000/290 | Roller table. Length 1000 mm, width of cylinders 290 mm, capacity 200 kg/m, adjustable | O | |

| RD 2000/290 | Roller table. Length 2000 mm, width of cylinders 290 mm, capacity 200 kg/m, adjustable | O | |

| RB 200 | Side vertical fix cylinder, height 200 mm, monted on the RD tables | O | |

| RD VR-290 | Robust cylinder length 290 mm with the bearing for RD roller coneyor. The capacity of roller table increased from 200 kg/m to 400 kg/m | O | |

| RBS 200/290 | Side vertical movable cylinder, height 200 mm, working only with RB. | O | |

| RHS 290 | Horizontal cylinder , working only together with RB + RBS for bundle fixing, length of cylinder 290 mm | O | |

| RDN | Support for RD. | O | |

| R290 | Movable cylinder, adjustable height, width 290 mm, capacity 200 kg. | O |

Tech. data NO241 are valid on 1.1.2024. Producer has the right to make changes of technical data.

Values contained on this page are only for information purposes. This information is not an offer and is not a public promise. This indicative offer does not give right to close a contract. The only guiding document for the contract is a valid price list.

or send inquiry!