| mm | 0° | 45° | 60° | -45° | -60° |  |

|

|---|---|---|---|---|---|---|---|

|

220 | 160 | 90 | x | x | x | |

|

120* | 85* | 55* | x | x | x | |

|

230X190 | 160X90 | 90x90 | x | x | 230x120 |

|

|

|

|

|

|---|---|---|---|---|

| 3x400V | 0,75/1,1 | 30/65 | 2450x27x0,9 | 260 |

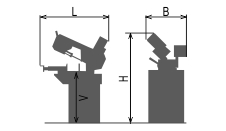

| Lmin | Lmax | Bmin | Bmax | Hmin | Hmax | V |

|---|---|---|---|---|---|---|

| 1200 | 1200 | 650 | 650 | 1800 | 925 |

Manual band saw machine with full manual manipulation.

The machine is designed for cutting of material in vertical and angle cuts, angle cuts are possible to set fluently from 0 to 60 grades to the right. Change of angle using quick clamping handle.

It is suitable for piece production and small series production. Thanks to its robust construction it enables cutting of wide range of profiles and full materials.

Construction:

The machine is constructionaly designed in that way, so that it corresponds to standard exertions in productive conditions. That is why all carrying parts are made as cast-iron castings (solidity, absorbtion of vibrations and stops). Parts of arm, vice and turn table is cust iron.

The arm of the machine is made of cust iron and it is designed to ensure the power and the precision of the cut. Arm is 25 grades sloped, it increases the lifetime of blade.

Down working positions of the arm are controlled by the cam and microswitches. The arm stops automatically after reaching the down position. The arm is lifted by the operator manually.

The vice is made from cast iron. Jaws ensure safe clamping of the material.

The manually operating vice is situated in an adjustable dovetail groove and is equipped with a quick clamping.

Moving jaw of the vice is manual with a wheel and trapeze thread.

Turn table is cust iron. A turntable gives a big place for supportion of material and its perfect clamping.

Manuall turning of the table for angle cuts, angle fixation using quick clamping lever.

General angles are adjusted by the nonius.

Basic equipment of machine:

Leading of blade in hard-metal plates.

There is a guide situated on the firm beam on the drive side. On the tightening side there is the guide situated on the moving beam.

The guide beams of moving band guide is adjustable in whole working range. Manual adjustment and fixing of the guide beams.

Guide holder moves in adjustabled dovetail groof.

The saw-band is equipped with a guard, which protects the operator from millings and cutting emulsion.

Mechanic tightening of the blade.

Drive of machine is solved by worm gear box with pernament oil filling. Three phase engine with double winding, two cutting speeds. Termoprotection of engine.

The cooling system distributes cutting emulsion to the band guides.

Base with a tank for chips.

Indication of blade tightening and opening of the cover.

Controlling 24 V.

Basic equipment of machine:

Measuring end stop.

Band saw blade.

Set of spanners for common service.

Manual instructions in eletronic form (CD).

Operating cycle:

Complete manual operation, manually controlled quick clamping vice, manually leaded cut against the pressure of springs. The advantage is a sensitive feeling of the cut especially for a piece production. You start the machine by pressing the microswitch on the hand lever. You handle with the material manually. Turning the arm for angle cuts.

| Code | Description | Type |

|---|

Tech. data NO241 are valid on 1.1.2024. Producer has the right to make changes of technical data.

Values contained on this page are only for information purposes. This information is not an offer and is not a public promise. This indicative offer does not give right to close a contract. The only guiding document for the contract is a valid price list.