HISTORICAL BAND SAWS

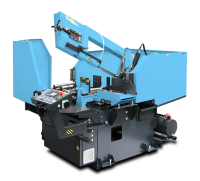

All working movements of an arm, a vice and feeders are manipulated by a hydraulic agregate. The arm is pushed by towards the cut by a doubleacting hydraulic cylinder. A speed and a force of a working movement are regulated. There is possible to make a lot of feeds. Number of pieces is set in the controlling panel, setting of a lenght is made manually. It is possible to choose an automatic or a semiautomatic regime where all movements are controlled independently. Angle cuts are possible.

| mm | 0° | 45° | 60° | -45° | -60° |  |

|

|

|

|---|---|---|---|---|---|---|---|---|---|

220x250 A-NC-R |

|

220 | 160 | 90 | x | x | 1,1/0,75 | 30/65 | 2450x27x0,9 |

230 AUTOMAT AFC (/ ESC) |

|

230 | 200 | 135 | x | x | 3,79/4,09 (4,09) | 30/70 (18-110) | 2760x27x0,9 |

230 AUTOMAT AFC - HRI (/ESC) |

|

230 | 200 | 135 | x | x | 3,79/4,09 (4,09) | 35/70 (18-110) | 2760x27x0,9 |

235 AUTOMAT NC |

|

235 | 180 | 110 | x | x | 1,3/1,8 | 40/80 | 2825x27x0,9 |

235 AUTOMAT CNC |

|

235 | 180 | 110 | x | x | 1,3/1,8 | 40/80 | 2825x27x0,9 |

240x280 A-NC-F |

|

260 | x | x | x | x | 2,2 | 20-100 | 2980x27x0,9 |

240x280 A-NC-R-F |

|

240 | 190 | 120 | x | x | 2,2 | 20-100 | 2980x27x0,9 |

240x280 A-CNC |

|

260 | x | x | x | x | 1,4/2,0 | 35/70 | 2980x27x0,9 |

240x280 A-CNC-F |

|

260 | x | x | x | x | 2,4 | 20-100 | 2980x27x0,9 |

240x280 A-CNC-R |

|

240 | 190 | 120 | x | x | 1,4/2,0 | 35/70 | 2980x27x0,9 |

240x280 A-CNC-R-F |

|

240 | 190 | 120 | x | x | 2,2 | 20-100 | 2980x27x0,9 |

290 AUTOMAT AFI-NC / ESC |

|

285 | 240 | 170 | 240 | x | 3,79/4,09 (4,09) | 35/70 (18-110) | 3380x27x0,9 |

290x290 A-CNC |

|

290 | x | x | x | x | 2,2 | 20- 100 | 3100x27x0,9 |

290x290 A-CNC-F |

|

290 | x | x | x | x | 2,2 | 20-100 | 3100x27x0,9 |

290x290 A-CNC-LR-F |

|

290 | 240 | 150 | 240 | x | 2,4 | 20-100 | 3100x27x0,9 |

290x290 X-CNC-1500-F |

|

290 | x | x | x | x | 2,4 | 20-100 | 3100x27x0,9 |

290x290 X-CNC-LR-1500-F |

|

290 | 240 | 150 | 240 | x | 2,2 | 20-100 | 3100x27x0,9 |

295 AUTOMAT NC |

|

290 | 265 | 220 | x | x | 0,9/1,6 | 37/75 | 3010x25x0,9 |

300x300 A-CNC |

|

290 | 260 | x | x | x | 1,5/2,0 | 35/70 | 4000x27x0,9 |

300x320 X-CNC-LR-1500 |

|

300 | 300 | 200 | 280 | x | 2,4 | 20-100 | 3660x27x0,9 |

350x400 A-CNC-LR |

|

350 | 320 | x | 320** | x | 3,0 | 20-100 | 4520x34x1,1 |

380 AUTOMAT CNC |

|

580 | x | x | x | x | 3,0 | 80-200 | 5350x34x1,1 |

X: Semiautomatic, hydraulically manipulated two column band saw machine. An unique construction of the band saw machine with three pulleys for leading of the blade. With the blade that is 8 grades sloped against the level guarantee high-efficiency of cutting. The machine is designed for vertical cuts. Highly efficient machine for cutting of construction steel of profile type. Secondary can be used for hardened material cutting.

X-CNC: Automatic two column band saw machine with complete hydraulic control. The machine is designed for vertical cuts. An unique construction of the band saw machine with three pulleys for leading of the blade. With the blade that is 8 grades sloped against the level guarantee high-efficiency of cutting. Highly efficient machine for cutting of construction steel of profile type. Secondary can be used for hardened material cutting.

| mm | 0° | 45° | 60° | -45° | -60° |  |

|

|

|

|---|---|---|---|---|---|---|---|---|---|

TDC-600SA |

|

600 | x | x | x | x | 4,0 | 20-100 | 6230x41x10,3 |

TDC-600CNC |

|

600 | x | x | x | x | 4,0 | 20-100 | 6230x41x1,3 |

600 CAMEL X |

|

620 | x | x | x | x | 7,5 | 20-100 | 6040x41x1,3 |

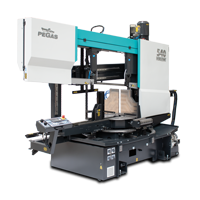

A band saw machine with an unique conception of a two- column version and of a movable working table. The table serves for a fixing of material and its precise setting. There is possible to change a level of a blade, it enables to make vertical as well as horizontal cuts.

| mm | 0° | 45° | 60° | -45° | -60° |  |

|

|

|

|---|---|---|---|---|---|---|---|---|---|

850x1000 GOLEM |

|

850 | x | x | x | x | 11,0 | 15-80 | 9080x67x1,6 |

1200x1600 GOLEM |

|

1200 | x | x | x | x | 11,0 | 15-80 | 11650x80(67)x1,6 |

Manually controlled quick clamping vice, cut is regulated by a hydraulic damper and a restrictor choke valve. A course of a cut is not influenced by a human factor and it causes a higher bladelife. A operator starts a machine pressing button START and sets a cutting speed. After finnishing the cut machines stops itself automatically and an operator lifts the arm manually to the start posittion. Feeding of material is manual. Angle cuts are possible by arm turning.

| mm | 0° | 45° | 60° | -45° | -60° |  |

|

|

|

|---|---|---|---|---|---|---|---|---|---|

250x315 GH-LR |

|

250 | 190 | 120 | 170 | x | 0,75/1,1 | 37/74 | 2825x27x0,9 |

180 POPULAR STANDARD GSH |

|

180 | 140 | 100 | x | x | 0,85/1,3 | 30/60 | 2300x20x0,9 |

210 POPULAR PLUS GSH |

|

210 | 190 | 130 | 190 | x | 0,85/1,3 | 35/70 | 2530x20x0,9 |

185 POPULAR |

|

185 | 170 | 105 | x | x | 0,6/0,8 | 40/80 | 2450x27x0,9 |

230 POPULAR STANDARD GSH |

|

230 | 200 | 135 | 180 | x | 1,5/1,8 | 35/70 | 2760x27x0,9 |

230 POPULAR PLUS GSH |

|

230 | 200 | 135 | 180 | x | 1,5/1,8 | 35/70 | 2760x27x0,9 |

235 POPULAR |

|

230 | 200 | 115 | 150 | x | 0,75/1,1 | 40/80 | 2825x27x0,9 |

235 EKO POPULAR |

|

230 | 210 | 135 | x | x | 0,75/1,1 | 40/80 | 2825x27x0,9 |

235x300 GH-LR-F |

|

235 | 200 | 115 | 140 | x | 1,1 | 20-100 | 2825x27x0,9 |

235x300 GHI-LR |

|

235 | 220 | 115 | 140 | x | 0,75/1,1 | 40/80 | 2825x27x0,9 |

235x300 GHI-LR-F |

|

235 | 200 | 115 | 140 | x | 1,1 | 20 - 100 | 2825x27x0,9 |

235x315 GH |

|

235 | 210 | 135 | x | x | 0,75/1,1 | 40/80 | 2825x27x0,9 |

235x315 GH-F |

|

235 | 210 | 135 | x | x | 1,1 | 20-100 | 2825x27x0,9 |

240x280 GH-R |

|

240 | 180 | 110 | x | x | 1,4/2,0 | 35-70 | 2980x27x0,9 |

240x280 GH-LR |

|

240 | 180 | 110 | 190 | x | 1,4/2,0 | 35/70 | 2980x27x0,9 |

290 POPULAR GH |

|

285 | 240 | 170 | 240 | x | 1,5/1,8 | 35/70 | 3380x27x0,9 |

290x320 GH-LR |

|

290 | 240 | 150 | 240 | x | 1,4/2,0 | 35/70 | 3100x27x0,9 |

295x400 GH-LR |

|

295 | 240 | 140 | 180 | x | 0,9/1,7 | 37/75 | 3010x27x0,9 |

300x400 GHI |

|

300 | 260 | 160 | x | x | 1,5/2,0 | 35/70 | 4000x27x0,9 |

350x400 GHI-LR |

|

350 | 300 | x | 300 | 280 | 2,6/3,1 | 35/70 | 4520x34x1,1 |

Two-column band saw machines for vertical cuts. There is the construction with the pre-tight linear bearings.This rugged machine is suitable for cutting of full materials with the attention to the cutting performance. The hydraulic agregate controlls all working functions of the semiautomatic machine.

CNC= the completely numerically controlled automat with the material feeder with the possibility of setting of several programms for setting of numbers and lenghts of cutted materials.

| mm | 0° | 45° | 60° | -45° | -60° |  |

|

|

|

|---|---|---|---|---|---|---|---|---|---|

400x400 HERKULES X |

|

400 | x | x | x | x | 4,0 | 20-100 | 5580x41x1,3 |

DC-400CNC |

|

415 | x | x | x | x | 4,0 | 20-100 | 5580x41x1,3 |

DC-400CNC-2 |

|

415 | x | x | x | x | 4,0 | 20-100 | 5580x41x1,3 |

300x300 HERKULES A-CNC |

|

300 | x | x | x | x | 3,0 | 20-100 | 4520x34x1,1 |

510x510 HERKULES X |

|

510 | x | x | x | x | 7,5 | 15-80 | 6060x54x1,6 |

DC-510CNC |

|

510 | x | x | x | x | 7,5 | 15-80 | 6060x54x1,6 |

850x1000 HERKULES X-VS |

|

850 | x | x | x | x | 11,0 | 15-80 | 9490x67(80)x1,6 |

SHI / X: Highly productive, semi-automatic dual column band saw machine. The saw is designed for cutting material in both straight and angular cuts, angular cuts adjustable 150° left, 90° perpendicular, 30° right (+/- 60 degrees). The saw is designed for cutting bars of solid material and profiles. Saw is used in series production in industrial plants. The saw is designed for cutting straight bars of steel material.

A-CNC / X-CNC: Highly productive, automatic dual column band saw with multiple material feeding The saw is designed for cutting material in both straight and angular cuts, angular cuts adjustable 150°left, 90°perpendicular, 30°right (+/- 60 degrees). The saw is designed for cutting bars of solid material and profiles. Saw is used in series production in industrial plants. The saw is designed for cutting straight bars of steel material.

| mm | 0° | 45° | 60° | -45° | -60° |  |

|

|

|

|---|---|---|---|---|---|---|---|---|---|

DCDS-600NC |

|

470 | 475 | 330 | 475 | 305 | 4,0 | 20-100 | 6060x34x1,1 |

DSDS-600SA |

|

470 | 475 | 330 | 475 | 305 | 4,0 | 20-100 | 6060x34x1,1 |

500x750 HORIZONTAL X II Generation |

|

500 | 500 | 330 | 500 | 300 | 5,5 | 20-100 | 6500x41x1,3 |

DCDS-750CNC |

|

500 | 500 | 330 | 500 | 300 | 5,5 | 20-100 | 6500x41x1,3 |

DCDS-750SA |

|

500 | 500 | 330 | 500 | 300 | 5,5 | 20-100 | 6500x41x1,3 |

290 HORIZONTAL HRI (/ESC) |

|

285 | 240 | x | 240 | x | 1,5/1,8 | 35/40 (18-110) | 3380x27x0,9 |

500x750 HORIZONTAL X-NC-2000 |

|

500 | 500 | 330 | 500 | 300 | 5,5 | 20-100 | 6500x41x1,3 |

440x600 HORIZONTAL X-NC-2000 |

|

470 | 475 | 330 | 475 | 305 | 4,0 | 20-100 | 6060x34x1,1 |

It is a highly efficient automatic hydraulically controlled band-saw with multiple material feeding.

The band saw machine is designed for cutting in automatic cycle perpendicularly as well as angularly. It enables angle cuts to the right 0 - 60 degrees and left 0-45 degrees. Automatic turning to angular cuts is a pert of cutting.

| mm | 0° | 45° | 60° | -45° | -60° |  |

|

|

|

|---|---|---|---|---|---|---|---|---|---|

340 KATANA A-CNC-R |

|

350 | 350 | 230 | x | x | 3,0 | 20-100 | 4780x34x1,1 |

The manual band saw machine MAN with the complete manual service, manualy controlled quick clamping vice, manually controlled cut led towards the press of the springs. The advantage of this machine is especially the sensitive feeling of the cut course, especially for a piece production. The material is moved manually. It is possible to turn the arm to make angle cuts.

| mm | 0° | 45° | 60° | -45° | -60° |  |

|

|

|

|---|---|---|---|---|---|---|---|---|---|

150x200 MAN |

|

150 | 110 | x | x | x | 0,6/0,8 | 40/75 | 2060x20x0,9 |

220x250 MAN-R |

|

220 | 160 | 90 | x | x | 0,75/1,1 | 30/65 | 2450x27x0,9 |

235x300 MAN-LR |

|

235 | 200 | 115 | 140 | x | 0,75/1,1 | 40/80 | 2825x27x0,9 |

235x300 MAN-LR-F |

|

235 | 200 | 115 | 140 | x | 1,1 | 20-100 | 2825x27x0,9 |

A band saw machine with an unique conception of a two- column version and of a movable working table. The table serves for a fixing of material and its precise setting. There is possible to change a level of a blade, it enables to make vertical as well as horizontal cuts.

| mm | 0° | 45° | 60° | -45° | -60° |  |

|

|

|

|---|---|---|---|---|---|---|---|---|---|

1250x1600 PORTAL |

|

1250 | x | x | x | x | 12,5 | 18-80 | 11650x80x1,6 |

It is a highly efficient automatic hydraulically controlled band-saw with multiple material feed. The machine has massive design, it is robust and has new conception of friendly control system. The blade is sloped 7 degrees to cutting table, which enables better performance during cutting of profiles as well as full materials and enables long lifetime of blade. These parameters together with powerfull drive and blade 34 mm heigh enable high productivity of machine. The machine is designed for vertical cuts. It is suitable for serial production in industrial premises. The machine is designed to saw steel materials, but also non-ferrous and light metals. However, we recommend consulting the manufacturer about this option. No other materials may be sawn without approval from the manufacturer.

| mm | 0° | 45° | 60° | -45° | -60° |  |

|

|

|

|---|---|---|---|---|---|---|---|---|---|

550x1300 Profi X |

|

610 | x | x | x | x | 11,5 | 20-100 | 9000x54x1,6 |

400 PROFI SHI |

|

400 | x | x | x | x | 3,0 | 20-100 | 4520x34x1,1 |

A hydraulic semiautomatic band saw machine SHI with a complete hydraulic controll. The machine is equipped by a controll system and by a hydraulic agregate which after the starting a cycle controlls vice clamping, cut, arm lifting to a selected location and vice opening. The arm of machine is pushed towards the cut by a double acting hydraulic cylinder with a possible regulation of a press and rate of flow. Material is manually manipulated. Turning arm for angle cuts.

| mm | 0° | 45° | 60° | -45° | -60° |  |

|

|

|

|---|---|---|---|---|---|---|---|---|---|

250x315 SH-LR |

|

250 | 190 | 120 | 170 | x | 0,75/1,1 | 37/74 | 2825x27x0,9 |

230 PROFESIONAL PLUS SHI (/ ESC) |

|

230 | 200 | 135 | 180 | x | 1,5/1,8 | 35/70 | 2760x27x0,9 |

230 PROFESIONAL STANDARD SHI (/ ESC) |

|

230 | 200 | 135 | x | x | 1,5/1,8 | 35/70 | 2760x27x0,9 |

235 EKO PROFESIONAL |

|

235 | 200 | 135 | x | x | 0,75/1,1 | 40/80 | 2825x27x0,9 |

230x280 SH-LR |

|

230 | 190 | 100 | 170 | x | 0,75/1,1 | 35/70 | 2720x27x0,9 |

300x320 SH-LR |

|

300 | 300 | 200 | 270 | x | 1,3/1,8 | 35/70 | 3660x27x0,9 |

235x300 SHI-LR |

|

235 | 200 | 115 | 140 | x | 0,75/1,1 | 40/80 | 2825x27x0,9 |

235x300 SHI-LR-F |

|

235 | 200 | 115 | 140 | x | 1,1 | 20-100 | 2825x27x0,9 |

240x280 SHI-R-F |

|

240 | 180 | 110 | x | x | 2,2 kW | 20-100 | 2980x27x0,9 |

290 PROFESIONAL SHI (/ESC) |

|

285 | 240 | 170 | 240 | x | 3,79/4,09 | 35/70 | 3380x27x0,9 |

290x320 SHI-LR-F |

|

290 | 240 | 150 | 240 | x | 2,4 | 20-100 | 3100x27x0,9 |

295x400 SHI-LR-F |

|

295 | 240 | 140 | 180 | x | 1,7 | 20-100 | 3010x27x0,9 |

300x400 SHI-F |

|

300 | 240 | 150 | x | x | 1,50/2,00 | 20-100 | 4000x27x0,9 |

230x280 SHI-LR AKCE |

|

230 | 190 | 100 | 170 | x | 1,5 | 20-100 | 2720x27x0,9 |

Tech. data NO241 are valid on 1.1.2024. Producer has the right to make changes of technical data.

Values contained on this page are only for information purposes. This information is not an offer and is not a public promise. This indicative offer does not give right to close a contract. The only guiding document for the contract is a valid price list.